Hydraulic Flow Control Valves: An In-Depth Look

Introduction

In hydraulic systems, controlling the flow of fluid is essential for regulating the speed of actuators and ensuring efficient system operation. Flow control valves are specifically designed components that manage fluid flow within a hydraulic system. In this article, we will explore four common types of flow control valves: check throttle valves, 3-way flow valves, pressure - compensated speed control valves, and flow - dividing valves, highlighting their advantages and typical applications.

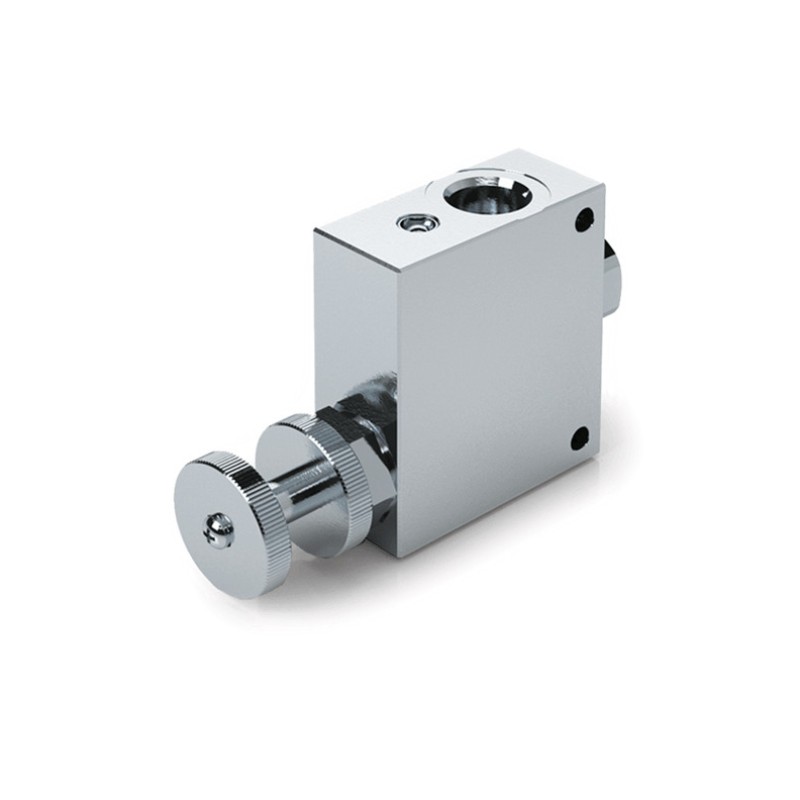

BARREL FLOW CONTROL VALVES WITH CHECK

barrel flow control valves with check are composed of a check valve and a throttle valve. They function as a check valve when fluid flows in one direction, allowing free passage, and as a throttle valve in the opposite direction, restricting flow. This dual functionality makes them ideal for applications where quick retraction of an actuator is needed while still maintaining controlled extension. They are often used in hydraulic systems to achieve stable pressure and speed调节during operation.

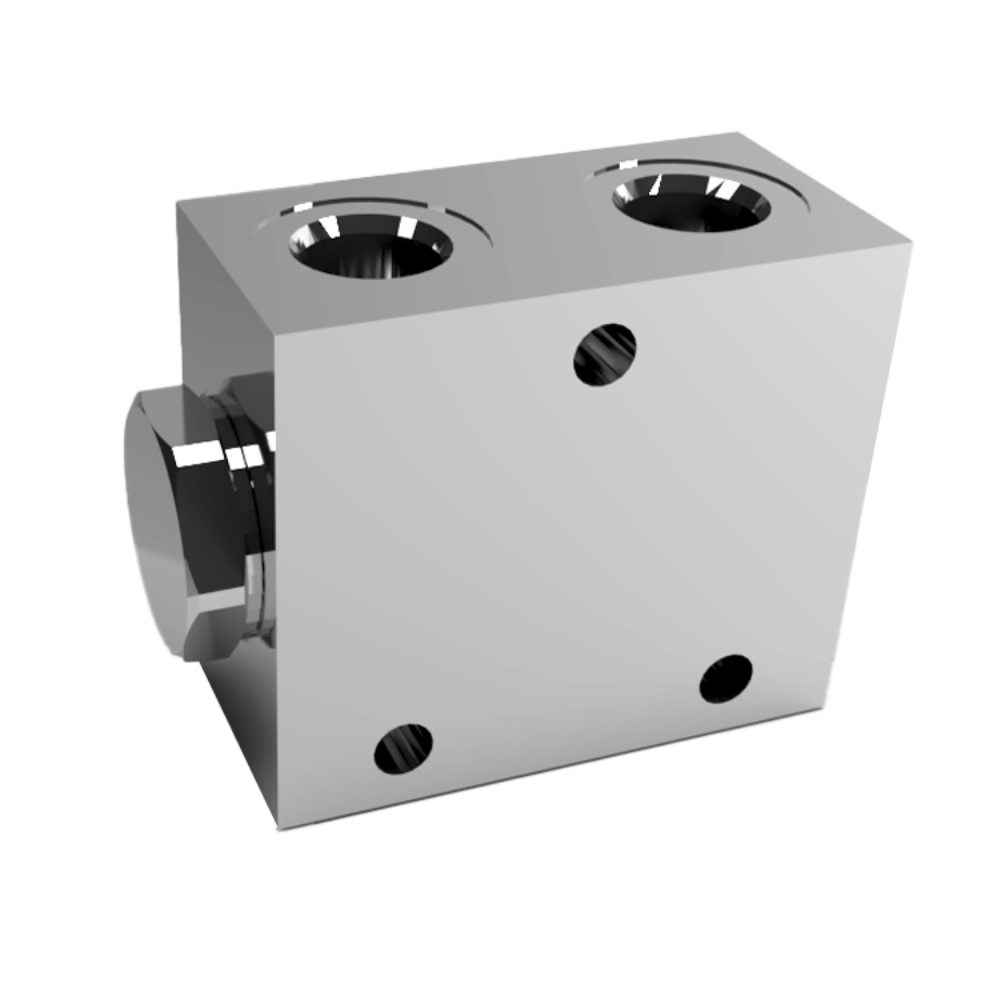

3 PORT FLOW CONTROL VALVE ONGOING PRESSURE LINE

3 port flow control valve ongoing pressure line consist of a relief valve and a throttle valve connected in parallel. The relief valve maintains a constant pressure drop across the throttle valve by diverting excess flow back to the reservoir. This allows the flow to the actuator to be precisely controlled based on the throttle valve's setting, independent of load variations. They are commonly used in load - sensing hydraulic systems, where maintaining a consistent pressure differential across the throttle valve ensures accurate flow and speed control. Three-way flow valves are particularly beneficial in multi - actuator systems, as they can prevent interference between different circuits and ensure each actuator receives the appropriate flow.

PRESSURE-COMPENSATED SPEED CONTROL VALVES

Pressure-compensated speed control valves are designed to maintain a constant flow rate despite fluctuations in system pressure. They achieve this by incorporating a pressure - compensating mechanism that adjusts the effective flow area to counteract pressure changes. These valves are useful in systems where load variations can cause significant pressure changes, ensuring stable actuator speed regardless of the load. They are often employed in applications such as hydraulic presses, where consistent force application, and speed control are critical for achieving high - precision production.

2 WAYS FLOW DIVIDER

2 ways flow divider distribute hydraulic fluid flow from a single source to multiple actuators or circuits in preset proportions. This ensures synchronized operation of multiple actuators, making them ideal for applications where precise coordination of movements is required. Flow-dividing valves can be designed to provide equal flow to each circuit or to allocate flow according to specific ratios. They are commonly used in applications like excavators and other heavy machinery, where multiple hydraulic cylinders need to extend and retract simultaneously for smooth and coordinated operation.

Conclusion

Hydraulic flow control valves play a crucial role in hydraulic systems by providing precise control over fluid flow. The check throttle valve, three-way flow valve, pressure - compensated speed control valve, and flow - dividing valve each offer distinct advantages and are suitable for different applications.

Understanding the characteristics and applications of these flow control valves enables hydraulic system designers and operators to select the appropriate valve for their specific needs, ensuring efficient and reliable system performance.