Hydraulic Gear Motors: Performance, Advantages, and Applications

Introduction

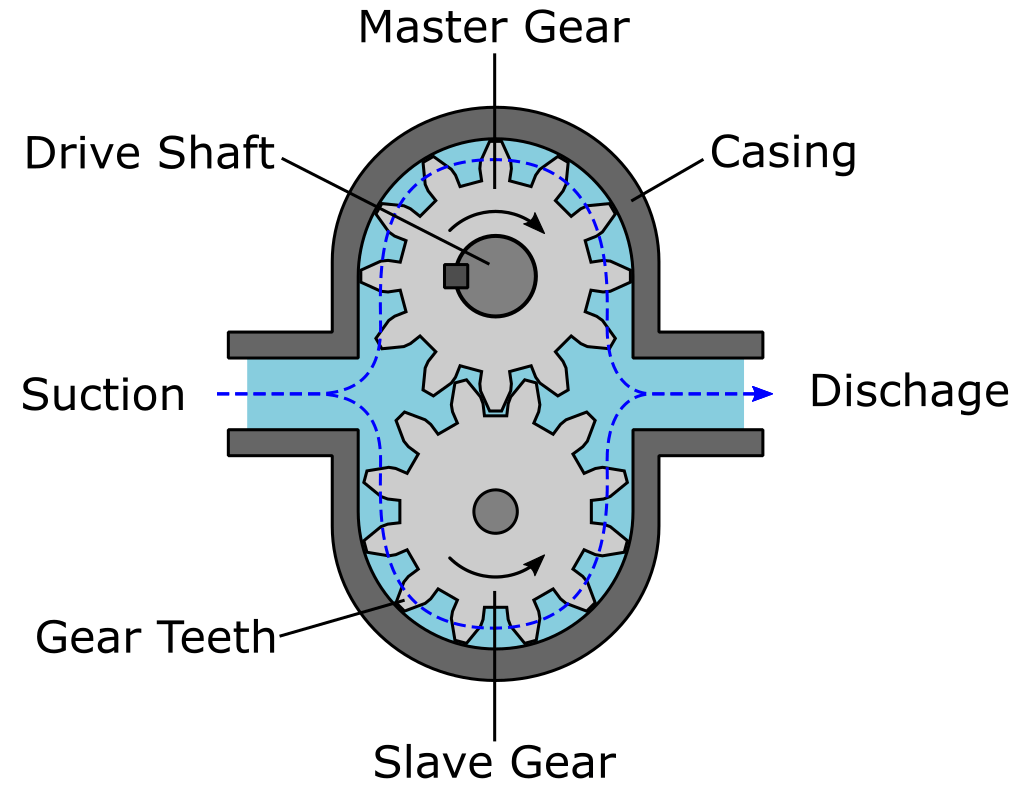

Hydraulic gear motors are essential components in various industrial and mobile machinery applications. They convert hydraulic pressure and flow into torque and angular displacement, providing efficient and powerful mechanical power. This article explores the performance, advantages, and applications of hydraulic gear motors, with a focus on their use in hydraulic wind cooling systems, wind power systems, and lubrication systems.

Performance and Advantages

Hydraulic gear motors offer several key performance benefits and advantages:

High Torque: They provide high torque capabilities, making them suitable for heavy-duty applications where significant rotational force is required.

Compact Design: Hydraulic gear motors are relatively compact compared to other types of motors, allowing for easier integration into machinery.

Efficiency: They operate with high efficiency, converting hydraulic energy into mechanical power effectively.

Durability: Built with high-strength materials, hydraulic gear motors are designed to withstand harsh operating conditions and provide long service life.

Cost-Effectiveness: They are generally less expensive than other types of hydraulic motors, such as piston or vane motors.

Applications

Hydraulic Wind Cooling Systems

Hydraulic gear motors are commonly used in hydraulic wind cooling systems. These systems require reliable and efficient motors to drive cooling fans and other components. The high torque and compact design of hydraulic gear motors make them ideal for this application, ensuring optimal cooling performance and longevity.

Wind Power Systems

In wind power systems, hydraulic gear motors play a crucial role in driving various mechanisms. They are used in pitch control systems, yaw drives, and hydraulic pumps. The ability to operate under extreme environmental conditions and provide consistent performance makes hydraulic gear motors a preferred choice in the wind energy sector.

Lubrication Systems

Hydraulic gear motors are also widely used in lubrication systems. They provide the necessary power to drive lubrication pumps and other components, ensuring proper lubrication of machinery. The reliability and durability of hydraulic gear motors make them suitable for continuous operation in demanding industrial environments.

Conclusion

Hydraulic gear motors offer exceptional performance and reliability, making them a popular choice for various applications. Their high torque, compact design, efficiency, durability, and cost-effectiveness make them suitable for use in hydraulic wind cooling systems, wind power systems, and lubrication systems. By understanding the performance characteristics and advantages of hydraulic gear motors, engineers and designers can select the appropriate motor for their specific application, ensuring optimal system performance and longevity.