The working principle of the axial piston pump used in the hydraulic system of trucks is as follows:

Basic Structure

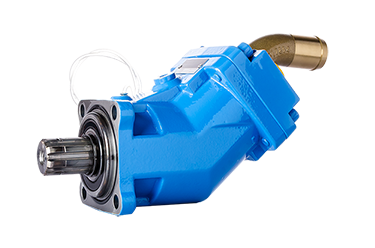

The axial piston pump mainly consists of the pump body, drive shaft, cylinder block, pistons, swash plate, and distribution plate. The drive shaft is connected to the pump body and drives the cylinder block to rotate. There are multiple pistons inside the cylinder block, which come into contact with the swash plate. The angle of the swash plate can be adjusted. The distribution plate is located on one side of the cylinder block and is used to control the intake and discharge of hydraulic oil.

Working Principle

Oil suction process: When the drive shaft rotates the cylinder block, the pistons move back and forth under the action of the swash plate. When the pistons move outward, the volume of the sealed working chamber inside the cylinder block increases, creating a negative pressure, and the hydraulic oil is sucked into the cylinder block through the oil suction port on the distribution plate.

Oil pressure process: When the pistons move inward, the volume of the sealed working chamber inside the cylinder block decreases, the hydraulic oil is compressed, the pressure increases, and it is discharged to the hydraulic system through the oil pressure port on the distribution plate.

Flow regulation: By changing the angle of the swash plate, the stroke of the pistons can be adjusted, thereby changing the displacement and flow rate of the pump. The larger the angle of the swash plate, the greater the stroke of the pistons, and the greater the displacement and flow rate of the pump; conversely, the smaller the angle of the swash plate, the smaller the stroke of the pistons, and the smaller the displacement and flow rate of the pump.

Application in Truck Hydraulic Systems

The axial piston pump is mainly used in truck hydraulic systems to drive various hydraulic actuators, such as lifting cylinders and steering cylinders. For example, in dump trucks, the axial piston pump provides power for the lifting of the cargo box, and the lifting and lowering of the cargo box are controlled through the hydraulic system to achieve the loading and unloading of goods. In the steering system of trucks, the axial piston pump supplies hydraulic oil to the steering cylinder to achieve steering control of the vehicle.

Advantages

High-pressure capability: The axial piston pump can provide a high working pressure, meeting the high-pressure requirements of the truck hydraulic system and ensuring that the hydraulic actuators can generate sufficient force to complete various tasks.

Convenient flow regulation: The flow rate can be adjusted by changing the angle of the swash plate, allowing the flow rate of the hydraulic system to be flexibly adjusted according to the working requirements of the truck, thereby improving work efficiency.

Compact structure: The structure of the axial piston pump is relatively compact, making it easy to install in the limited space of the truck and also helping to reduce the overall weight of the truck.

High efficiency: The volumetric efficiency of the axial piston pump is relatively high, providing a large flow rate and pressure at a low energy consumption, which helps improve the fuel economy of the truck.