Hydraulic Flow Dividers in Oil Drilling Machinery

Hydraulic flow dividers are essential components in the hydraulic systems of oil drilling machinery. They play a crucial role in distributing hydraulic fluid to multiple circuits, ensuring efficient and synchronized operation of various hydraulic components. In this article, we will discuss the applications and benefits of hydraulic flow dividers, hydraulic synchronous motors, and hydraulic distributors in oil drilling machinery.

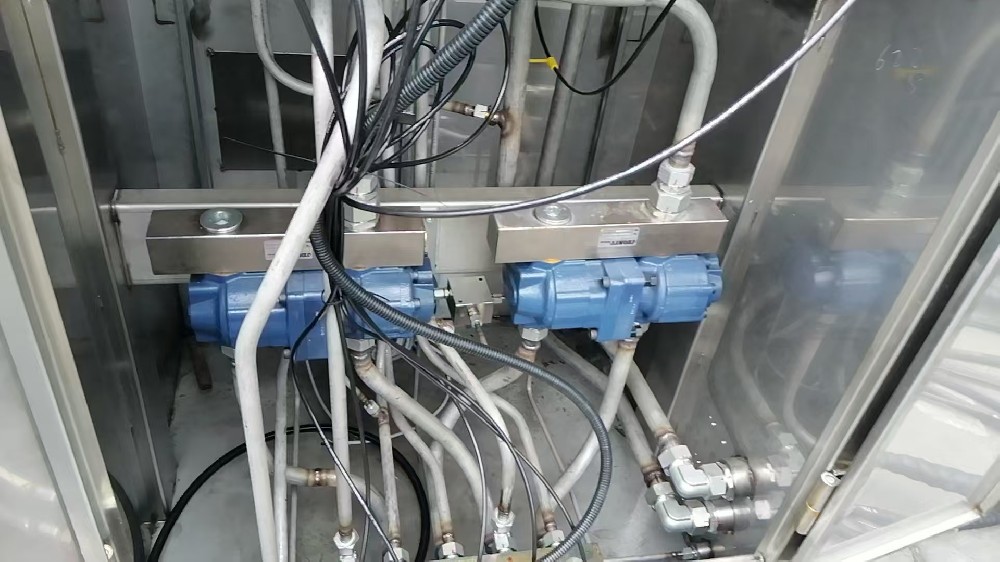

Applications of Hydraulic Flow Dividers

Hydraulic flow dividers are widely used in oil drilling machinery for various purposes. One of the key applications is in drill rigs, where they enable precise flow allocation and variable speed control. Two primary flows are directed to the drill motor for operation, while a third flow powers auxiliary services. The fourth flow is further divided to supply additional machine functions, such as drill rod screwing and unscrewing, ensuring seamless multitasking capabilities.

Benefits of Hydraulic Flow Dividers

Efficient Operation : Hydraulic flow dividers allow a single pump to power multiple circuits simultaneously, reducing energy consumption and costs. This eliminates the need for multiple pumps, simplifying the hydraulic system and improving overall efficiency.

Synchronized Movement : Flow dividers ensure that multiple hydraulic components, such as cylinders or motors, operate in synchronization. This is crucial in applications where precise movement control is required, such as lifting platforms or drilling operations.

High Pressure Resistance : Hydraulic flow dividers can withstand high working pressures, making them suitable for use in high - load and high - pressure environments.

Hydraulic Synchronous Motors

Hydraulic synchronous motors are another important component in oil drilling machinery. They are driven by hydraulic fluid and provide stable and reliable power output. These motors can maintain a constant speed, ensuring smooth operation of the hydraulic system. Hydraulic synchronous motors are widely used in hydraulic systems that require high efficiency and precision control, such as hydraulic power steering systems and industrial machinery.

Hydraulic Distributors

Hydraulic distributors, also known as control valves, are used to direct the flow of hydraulic fluid to different parts of the system. They play a crucial role in controlling the direction, pressure, and flow rate of the hydraulic fluid, ensuring efficient operation of the machinery. In oil drilling machinery, hydraulic distributors are used to control the movement of the drill bit and other hydraulic components, providing precise control and synchronization